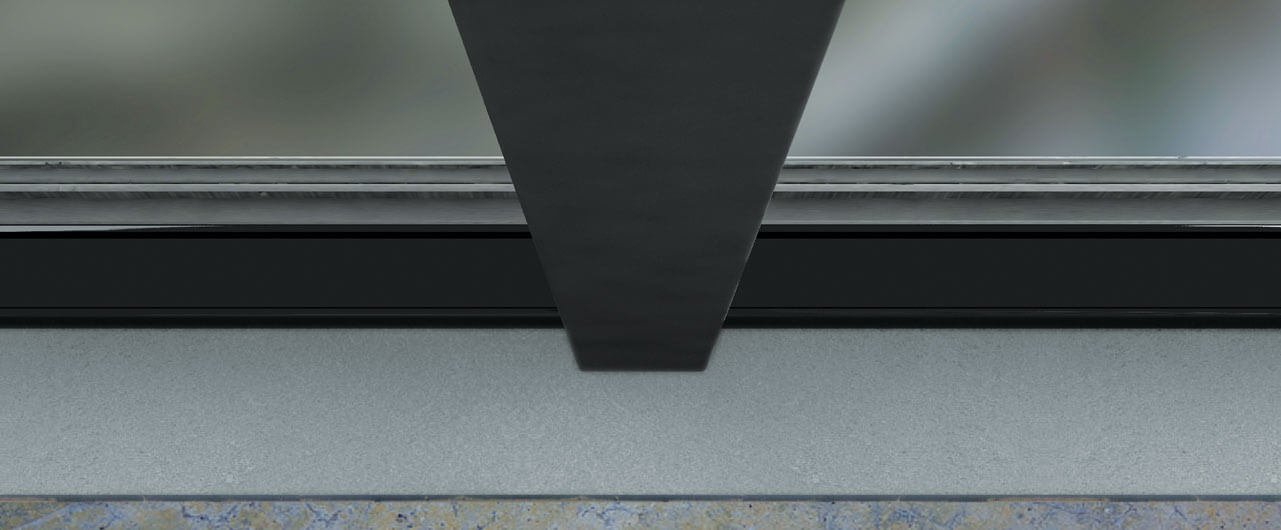

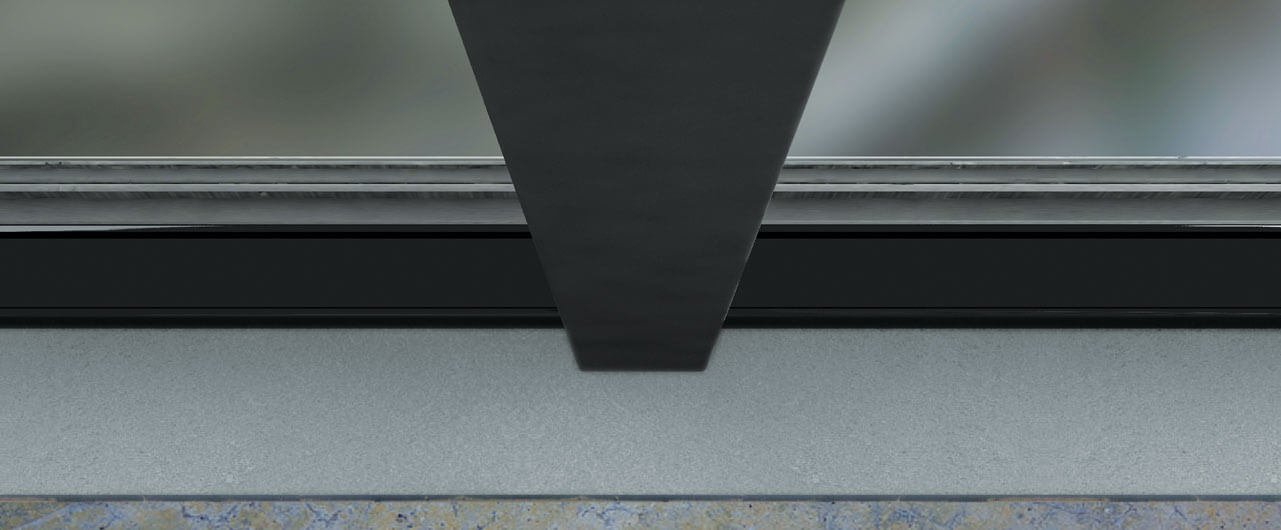

Fire Sealing System

Glass façades in high rise buildings have become a preferred architectural design element that lines most building in cities around the world. Specifically in glass façade buildings, a typical through gap is left between the glass facade and the floor ceilings. If these gaps are unsealed, they can be a passage for fire, smoke and fumes to spread rapidly. VS Panel Seal is a fire penetration sealing system that can effectively seal theses gaps and provide a fire seal. The system consists of mineral wool boards stuffed in the gaps between the façade and the ceiling with the exposed surfaces of the mineral wool boards being coated with Ace Mastik Coating, a fire-retardant coating. Any annular gaps between the Panel Seal System and the structure are sealed with Ace Mastik Sealant, a fire retardant sealant.

This fire rated sealing system will perform under fire conditions even after exposure to various conditions like weathering, aging, vibrations and ambient temperature variations.

VS Panel Seal is tested as per ASTM E 814 & UL 1479 for up to 4 hours fire rating.

FM approved, to approval class 4990 for 2 hrs. fire rating.

Fire rated sealing using Ace Panel seals does not get affected to required performance of the system during fire even after exposure to various conditions like weathering effects, aging, vibrations, ambient temperature variation.

It shows resistance to attack by rodents, vermin and termite.

The system also offers special features as below.

| PROPERTY | PRESENT VALUE |

| Life Expectancy | 40 Years |

| Density | 1.25 to 1.40 gms/cm3 |

| pH | 6.5 to 8.5 |

| Appearance | Off-White, thick liquid |

| Odor | Odorless |

| Flash Point | None |

| Resistance to moisture & humidity | Good |

| Toxicity | Non toxic |

| Application Temperature | 50 C to 500 C |

| Back filling Material details | Mineral Wool Board. Nominal Density 150 Kg/m3. Thickness 50 mm. |